Solutions

Logistics

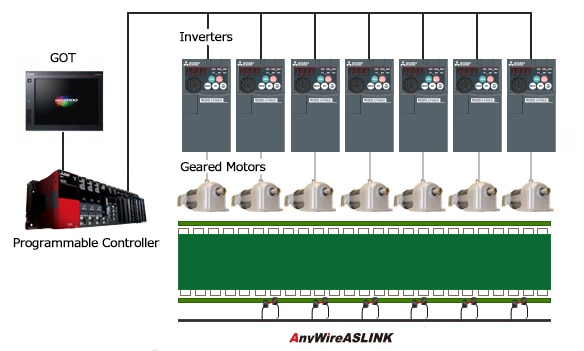

Carrying conveyor

Preventive maintenance and reduction of maintenance load

- Remote control and monitoring with networking FA products

- Detection of sensor status with reduced wiring using ASLINK

- UPS installed to handle power outage

Solution

- 1. Preventive maintenance is achieved via AnyWireASLINK sensors and vibration analysis by the combination of PLCs + geared motors + vibration sensors. Maintenance cost is reduced.

- 1) Sensor cable disconnections are detected by an ASLINKER (shorter time required to ascertain causes of device stops).

- 2) Photoelectric-type ASLINKSENSOR monitors the sensing level drop due to the stain on the light emitting/receiving surface.

- 2. Space saving achieved with the world's smallest class compact body and side-by-side installation of inverters.

- 3. Complicated connection and wiring bundle of sensor cable can by solved by introducing AnyWireAslink wire-saving system. Not only the routing being simplified, but the man-hours for startup can be significantly reduced.

System Configuration