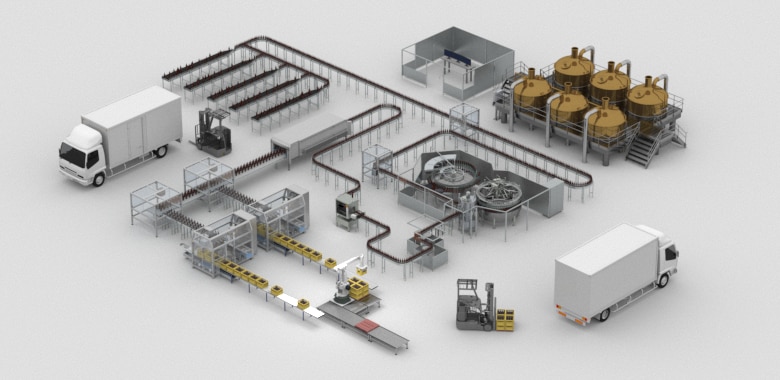

Mitsubishi Electric factory automation leverages the value chain across all aspects of manufacturing.

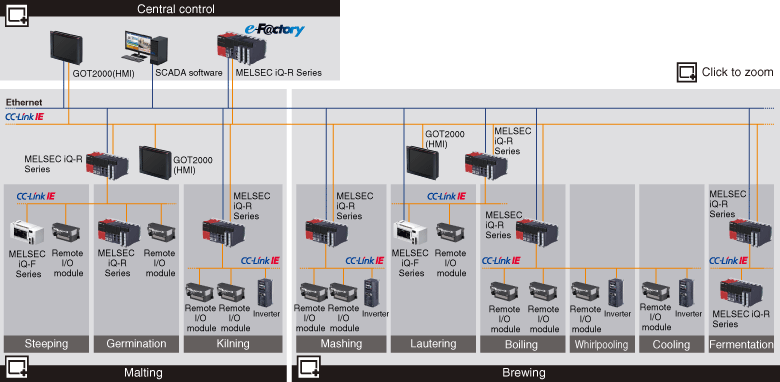

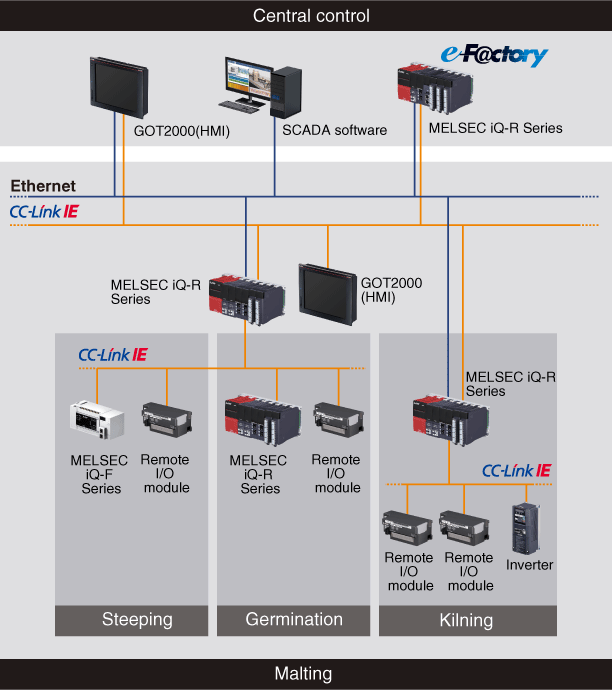

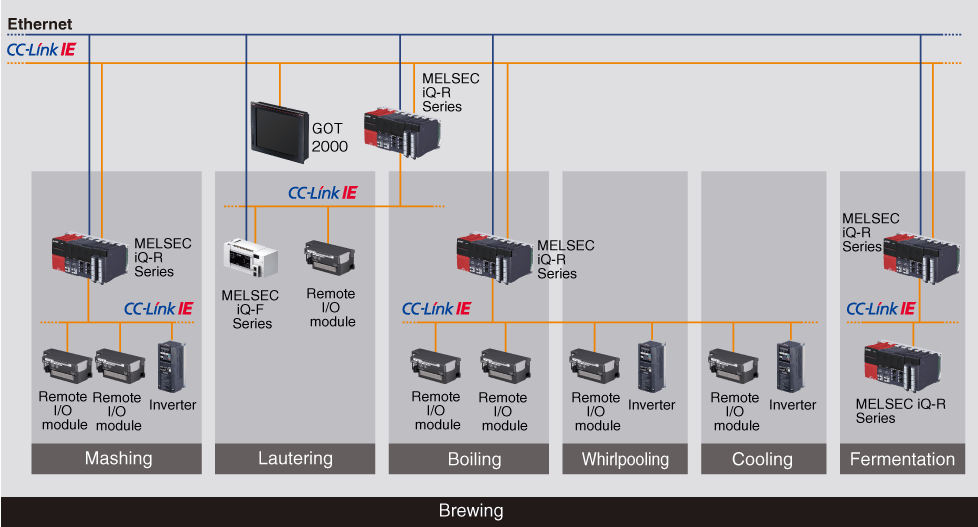

Brewery

Mitsubishi Electric factory automation incorporates a comprehensive range of products and solutions that can be easily applied across many different kinds of applications. With its extensive experience and capabilities, these solutions will help make your products more competitive and keep you one step ahead.

Click on each production process to see the solution in detail

Application-specific solutions

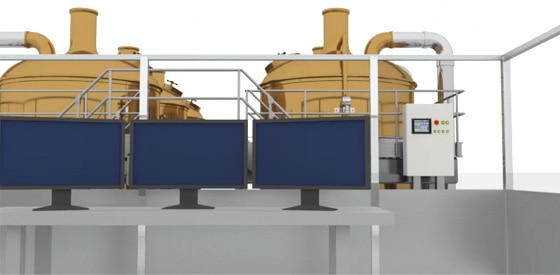

Brewing

BrewingThe creation of beer is an artisan skill handed down through generations, resulting in a distinct taste and appearance. The malting and brewing processes contain multiple sub-processes that require a multitude of stringent control processes for maintaining the pH, temperature, humidity, pressure, and other important elements. Utilizing a range of key technologies offered by Mitsubishi Electric factory automation products not only realizes a total process control solution, but also manages different processes on an industrial scale to ensure a superior product.

Users Benefit

- Accurate control of various process variables

- Flexible to multiple beer types through recipe management

- Plant-wide data management

- Reduce overall operating cost

Mitsubishi electric keeping you one step ahead of the competition

System example

Various innovative products helping you to realize the ideal system

Solution

Understanding and providing the solutions that fit correctly for you

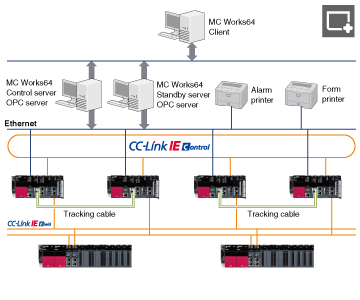

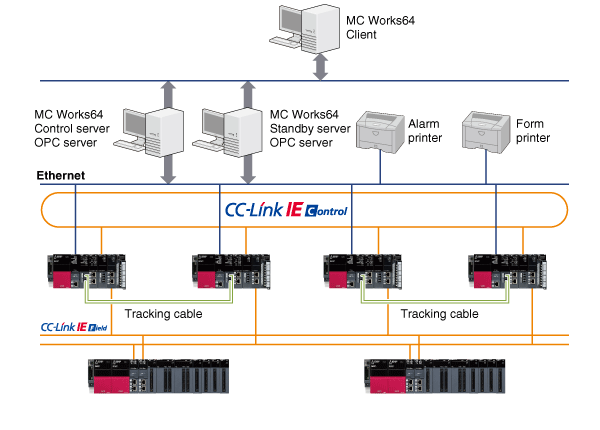

Productivity and quality improvement through plant-wide visualization

Next-generation supervisory control and data acquisition (SCADA) software supports e-F@ctory, providing extensive visualization and interconnectivity with factory automation products.

Solution

SCADA MC Works64

Mitsubishi SCADA MC Works64 is a next-generation software application that provides extensive visualization and enhanced interconnectivity with factory automation products. Improvements in productivity and quality can be realized through adoption of the SCADA system in areas such as plant-wide management, quality control, and production management.

Click here for details

Page Top

Easily realize a scalable, highly advanced process control system

Reduce development cost by integrating an intuitive engineering environment designed for process control.

Solution

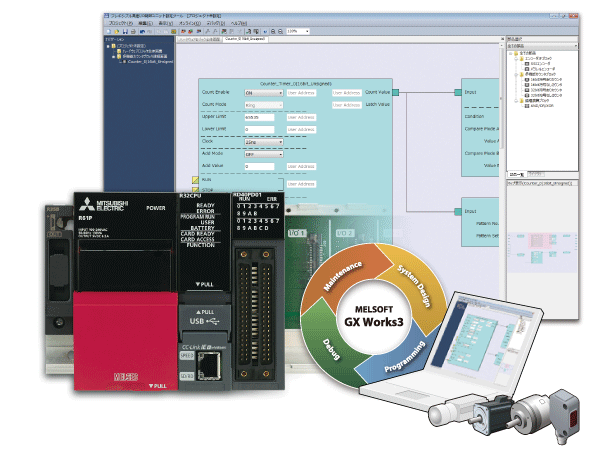

Programmable controller

engineering software

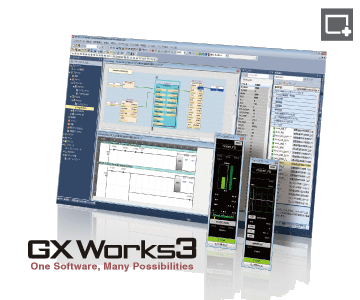

MELSOFT GX Works3

GX Works3, the standard integrated engineering software for the MELSEC iQ-R Series, makes programming process control systems relatively easy. The program editor uses function block diagram (FBD) language for process control, and simplifies system configuration with its intuitive features such as process tag label (variable) sharing, simple program structure, and easy project upload/download to the process CPU.

Click here for details

Page Top

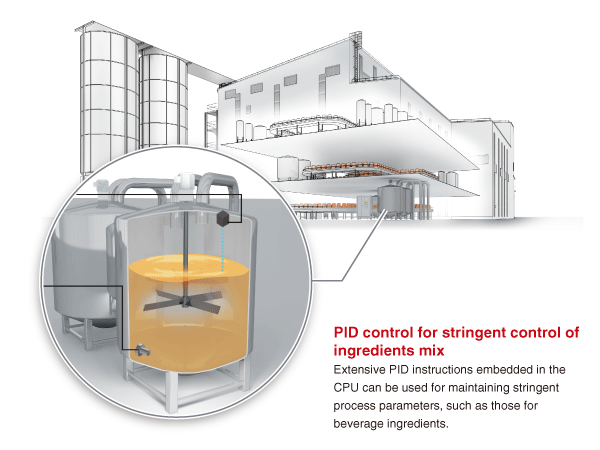

Maintaining beer quality through advanced process control

Process CPU with abundant process control instructions and dedicated algorithms integrates advanced PID and general control into one module.

Solution

MELSEC iQ-R Series

Process CPU

The process CPU provides high-speed performance coupled with the ability to handle large PID loops utilizing embedded PID control algorithms such as two-degrees-of-freedom PID, sample PI, and auto‑tuning support advanced process control. In addition, a single module can simultaneously execute general and process control, and cover wide-ranging process control applications, from small- to large-scale.

Click here for details

Page Top

Manage production and recipe data

Data management utilizing CPU internal database realizes easy and cost-efficient production management.

Solution

MELSEC iQ-R Series

CPU module internal database

Recipe and production data can be managed via the CPU internal database, which includes a selection of database commands that can add/delete/change records.

Click here for details

Page Top

Related products

Introducing various innovative products to solve your problems

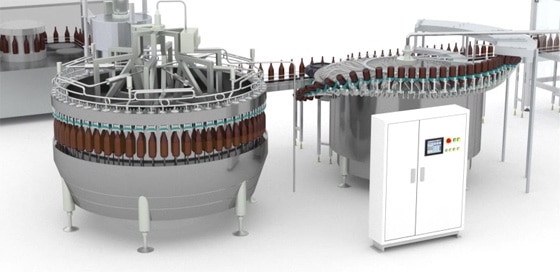

Filling/CIP

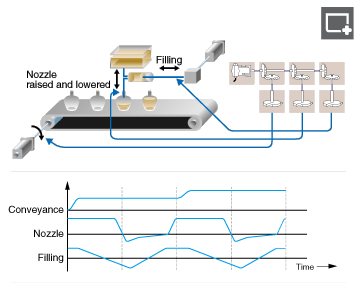

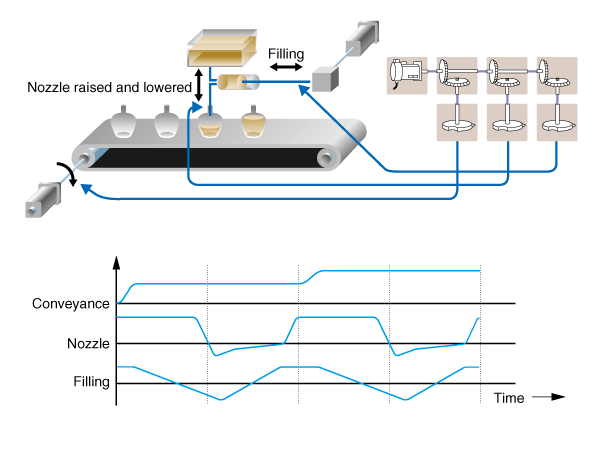

Filling/CIPProcess to fill bottles and cans with end-product beverage. To improve productivity, accurate and quick filling/sealing are basic requirements. Mitsubishi Electric factory automation products realize accurate nozzle control in accordance with the container shape and the amount of filler, as well as reduce changeover time and ensure effective measures against the entry of foreign matter, thereby contributing to improved productivity.

Users Benefit

- High-speed filling through accurate nozzle control

- Compact size and reduced space

- Remote monitoring reduces operator load

Mitsubishi electric keeping you one step ahead of the competition

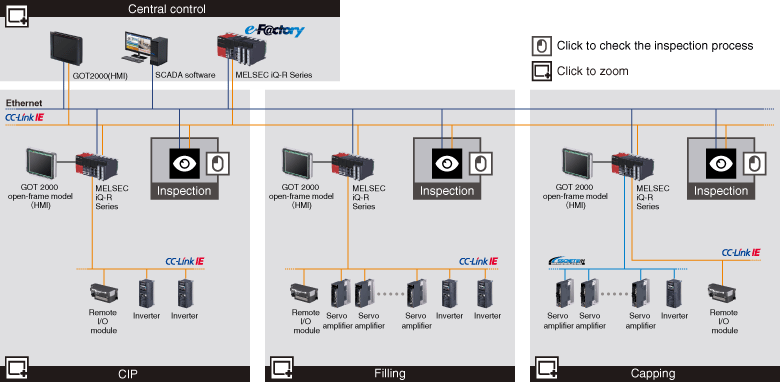

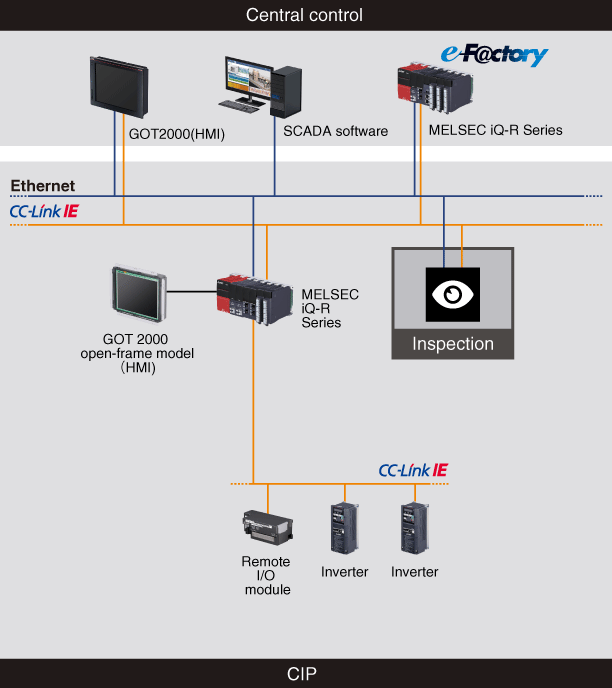

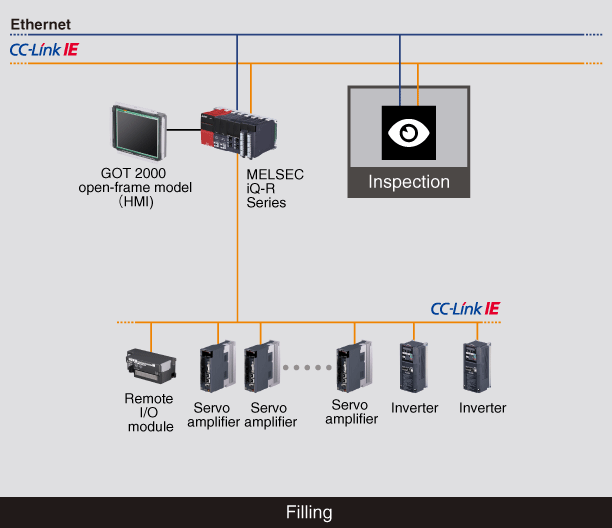

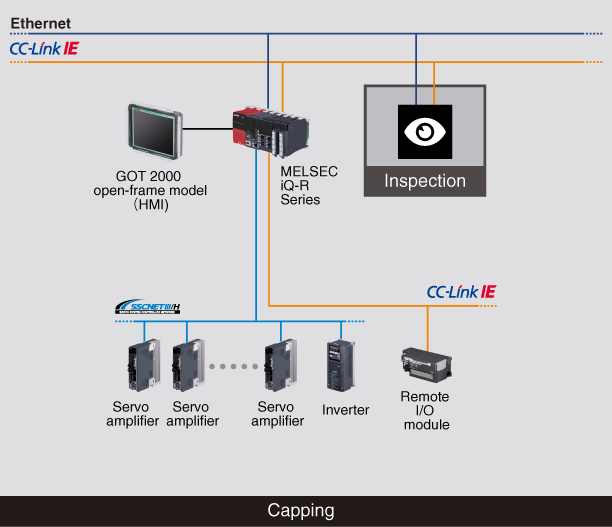

System example

Various innovative products helping you to realize the ideal system

Page Top

Solution

Understanding and providing the solutions that fit correctly for you

Nozzle control suppresses spatter and bubbling

Accurate nozzle lowering control in accordance with bottle shape and filling volume, and synchronized with the conveyor speed, is easily realized.

Solution

Servo system

Synchronized control/

Cam control

Software-based synchronized control is used as an alternative to mechanical control, such as gear, shaft, transmission and cam. Using electronic cam control, control of nozzle contact with liquid surface, amount of filler, and other functions can be realized easily.

Exchanging the cam when changing containers is also easy by simply changing the cam pattern.

Click here for details

Page Top

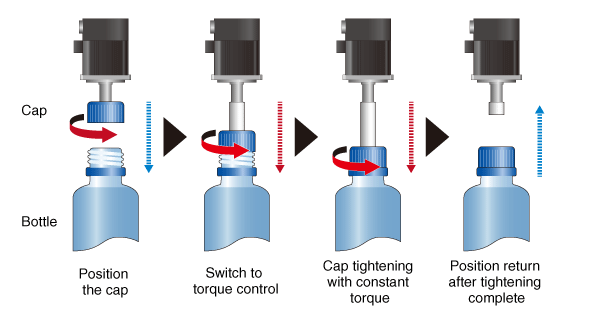

Highly accurate cap tightening without a sensor

Tighten caps quickly and correctly, doing so synchronized with conveyor speed and without using sensors such as a torque sensor.

Solution

Servo system

Tightening & press-fit control

Cap tightening time can be shortened as the torque control and speed control of the cap rotating axis can be smoothly switched according to the process. Open-loop control cap tightening is possible without using a torque sensor, reducing the number of devices necessary.

Click here for details

Page Top

Simple, user-friendly changeover

Changing materials, filling amount, and container shape can be easily done, reducing changeover time.

Solution

GOT(HMI)

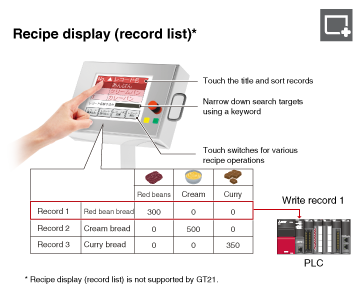

Recipe function/Recipe display

Recipe information such as product type and container shape are retained in the GOT(HMI), allowing necessary data to be written to the programmable controller. A list with recipe setting names can be displayed. Easy-to-clean open-frame models are also available.

Click here for details

Page Top

Remote monitoring easily visualizes the equipment status

The status of equipment in a remote area or areas where operators cannot easily enter can be checked easily.

Solution

GOT(HMI)

GOT(HMI) remote solution

In the clean room or on the shop floor where noise is often distracting, remote monitoring reduces operator load. Remote monitoring via GOT(HMI) allows monitoring of equipment in a remote area, realizing visualization of the factory.

Click here for details

Page Top

Related products

Introducing various innovative products to solve your problems

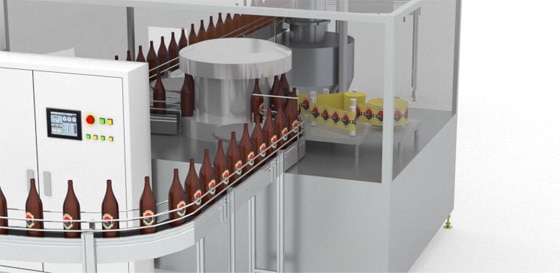

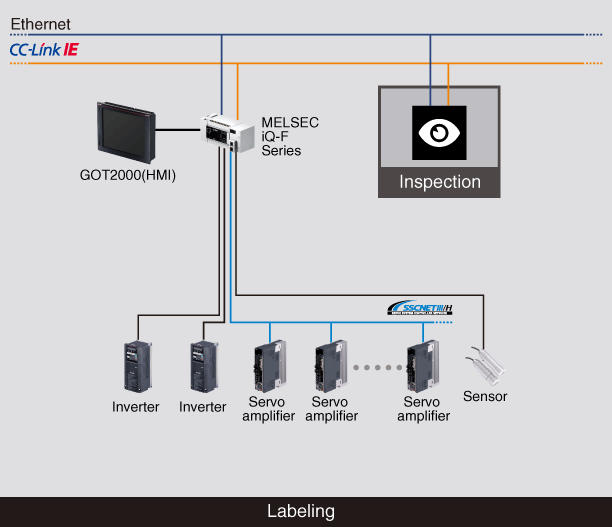

Labeling

LabelingProcess for printing letters such as expiration date and serial number, and then affixing product labels. Precision printing is necessary for food traceability (product tracing/ingredient tracing). Mitsubishi Electric factory automation products can ensure continuous quality by printing precisely and affixing product labels correctly in synchronization with high-speed conveyance systems, thereby reducing product loss.

Users Benefit

- Highly accurate labeling with clean finish

- Precision printing necessary for traceability

- Compact device and energy-saving operation

- Build safety and security in food system

Mitsubishi electric keeping you one step ahead of the competition

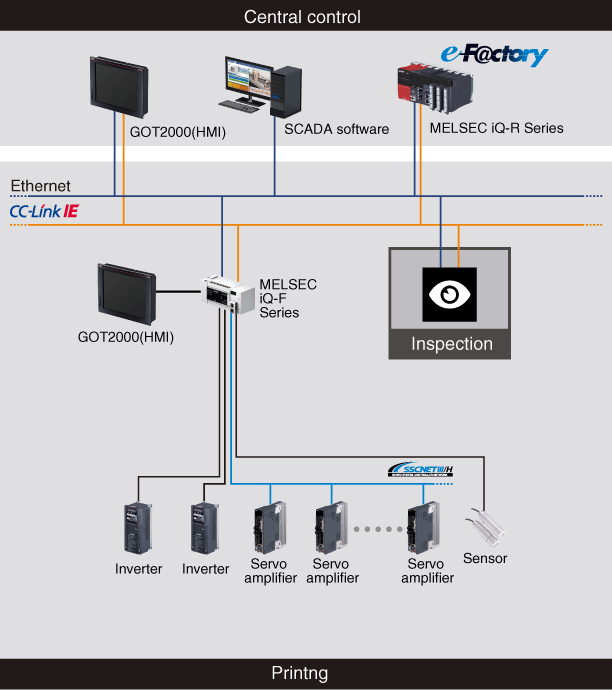

System example

Various innovative products helping you to realize the ideal system

Page Top

Solution

Understanding and providing the solutions that fit correctly for you

High-speed/High-accuracy labeling

Combination of synchronized control and cam control realizes highly accurate labeling synchronized with the conveyor speed.

Solution

Servo system

Synchronized control/

Cam control

Software-based synchronized control as an alternative to mechanical control, such as gear, shaft, transmission and cam. Synchronized control of conveyor and labeling equipment enables highly accurate labeling matching product conveyance speed (start, stop, and speed variation of conveyor system).

Click here for details

Page Top

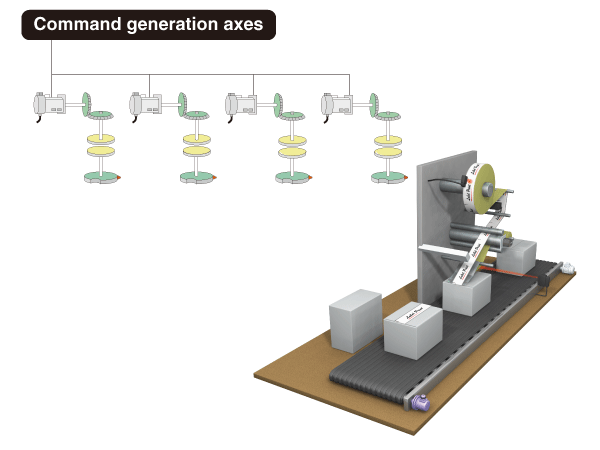

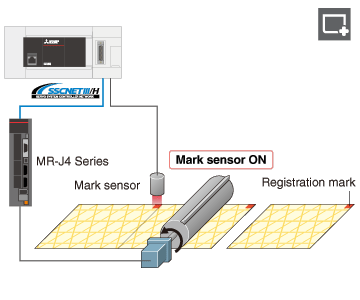

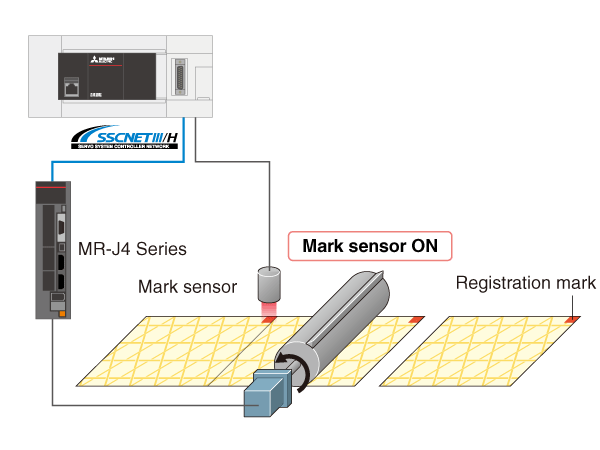

Constant label cutting using accurate position compensation

By compensating the cutter axis position error and workpiece position error at the time of affixing labels, uniform high-quality products are produced.

Solution

Servo system

Mark detection function

The actual position of the servo motor can be obtained based on inputs from the sensor.

The actual position of the servo motor can be obtained based on inputs from the sensor that detects marks on the high-speed workpieces moving along on the conveyor.

By compensating the workpiece position error based on inputs from the sensor, the label can be cut at the correct position.

Click here for details

Page Top

Pursuing equipment miniaturization and improved performance

Micro PLC with outstanding performance and extensive built-in functions realizes equipment miniaturization and improved performance.

Solution

Micro PLC

MELSEC iQ-F Series

Micro PLC is equipped with a high-speed system bus and enhanced built-in functions, and also supports a variety of networks. Many extension modules are available, contributing to equipment miniaturization and improved performance.

Click here for details

Page Top

Related products

Introducing various innovative products to solve your problems

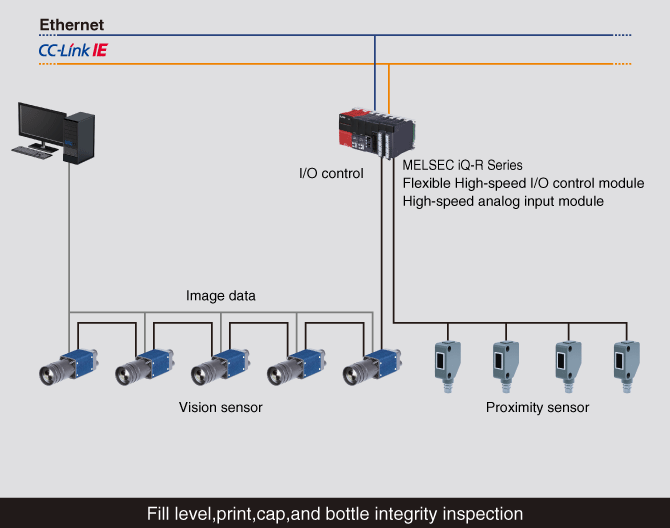

Inspection

InspectionEliminating defects and reducing downtime are basic requirements of automated systems, especially in the food and beverage industry where product quality is a top priority. Mitsubishi Electric offers a wide lineup of products capable of implementing and conducting inspections efficiently and at lower cost while maintaining the total quality of the manufactured product.

Users Benefit

- Diversified and accurate product inspection

- Precise defective product removal

- Seamless data collection and management

- Easy integration into main plant control system

Mitsubishi electric keeping you one step ahead of the competition

System example

Various innovative products helping you to realize the ideal system

Page Top

Solution

Understanding and providing the solutions that fit correctly for you

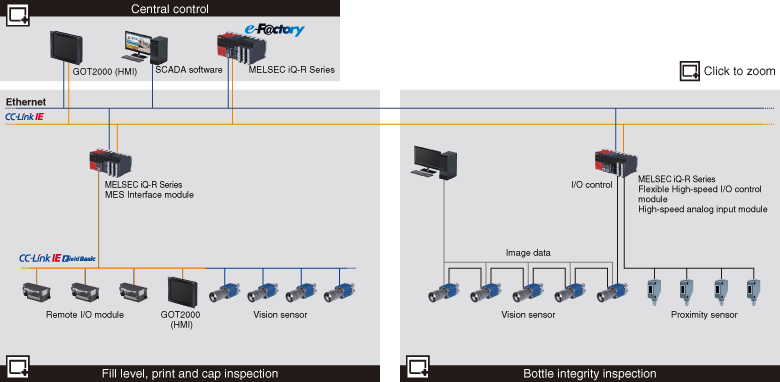

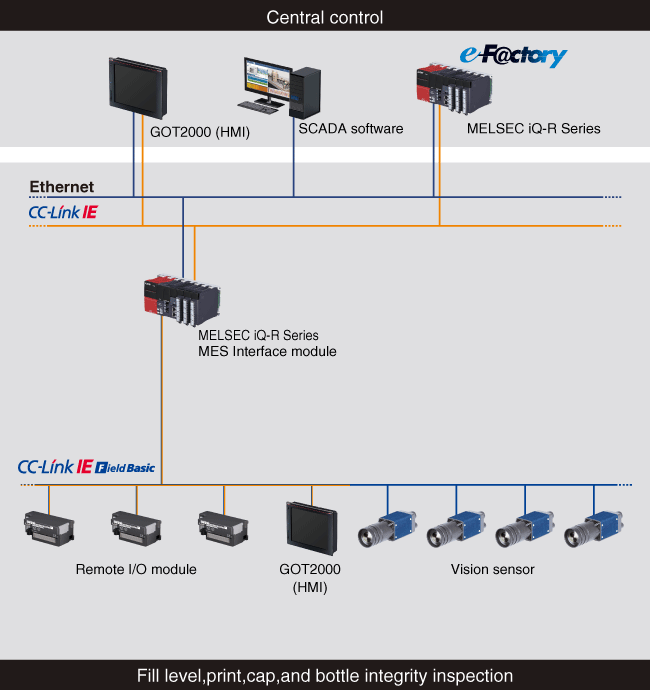

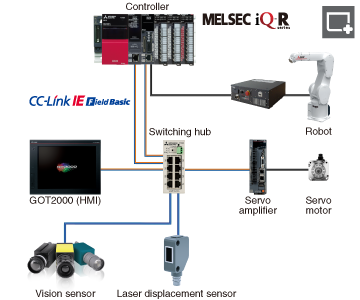

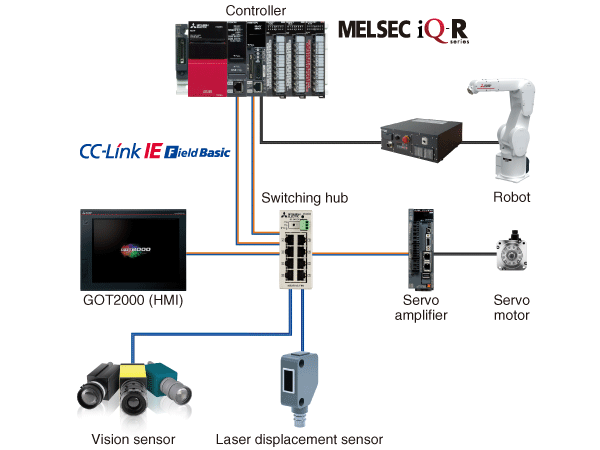

Integrating sensors and factory automation products

Ethernet-supported sensors can be used with CC-Link IE Field Network Basic, realizing the integration of sensors and factory automation products.

Solution

Ethernet-supported devices

compatible with

CC-Link IE Field Network Basic

Ethernet-supported vision sensors can be used together with CC-Link IE Field Network Basic, realizing a highly integrated inspection system. Overall system cost and engineering time can be reduced as compared to that incurred using two separate control systems.

Click here for details

Page Top

Ultrahigh-speed response synchronized with production line

Microsecond-fast response times enable reliable detection and removal of defective products moving at high-speed.

Solution

MELSEC iQ-R Series flexible high-speed I/O control module

The flexible high-speed I/O control module includes the ability to program control logic and send microsecond-fast asynchronous I/O responses to the programmable controller CPU and control bus, realizing stable machine performance and minimizing processing speed fluctuation. Used together with the dedicated configuration tool, the essential design processes associated with FPGA are no longer required, thereby reducing overall development cost.

Click here for details

Page Top

Related products

Introducing various innovative products to solve your problems

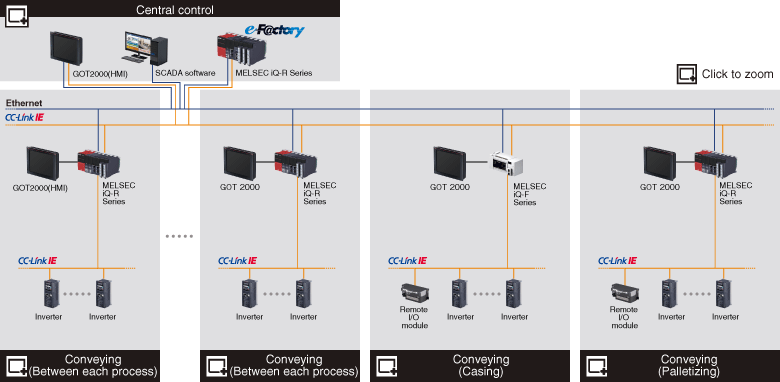

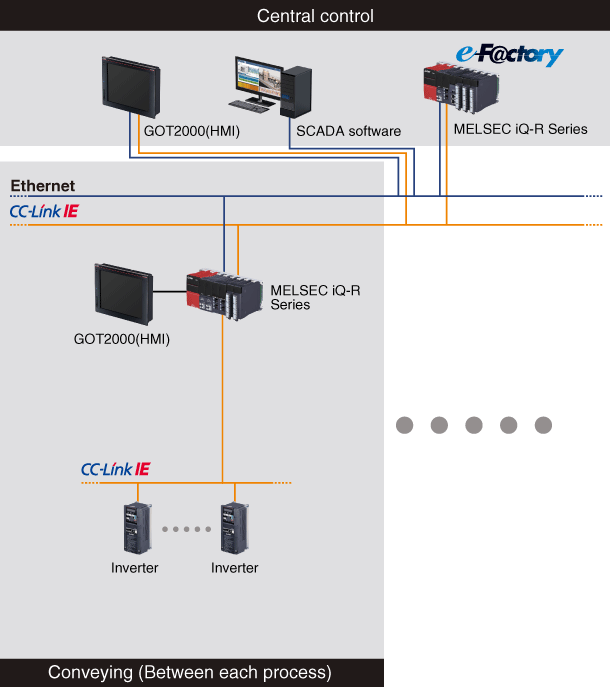

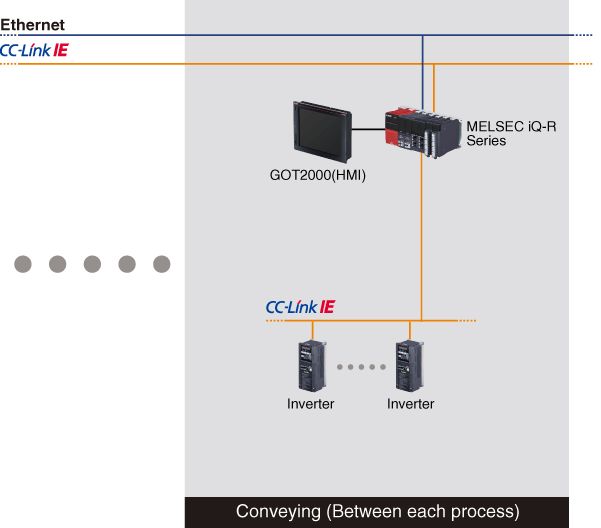

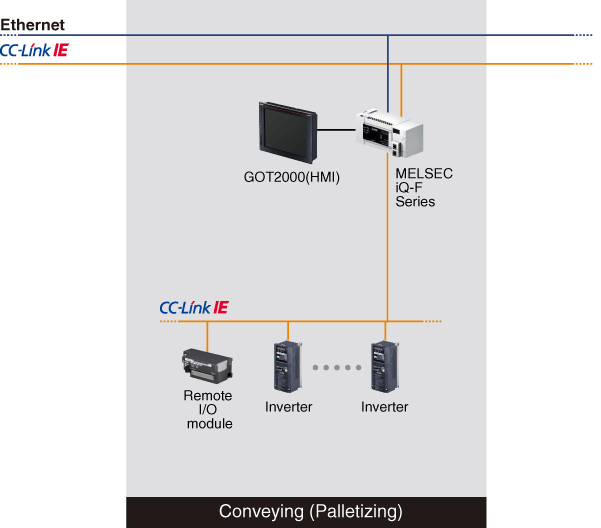

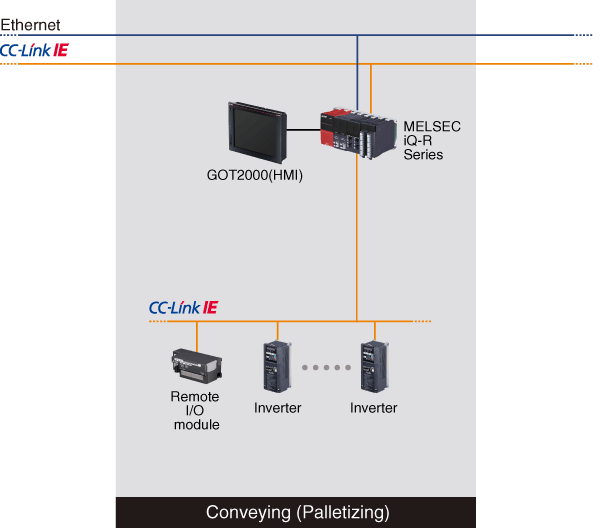

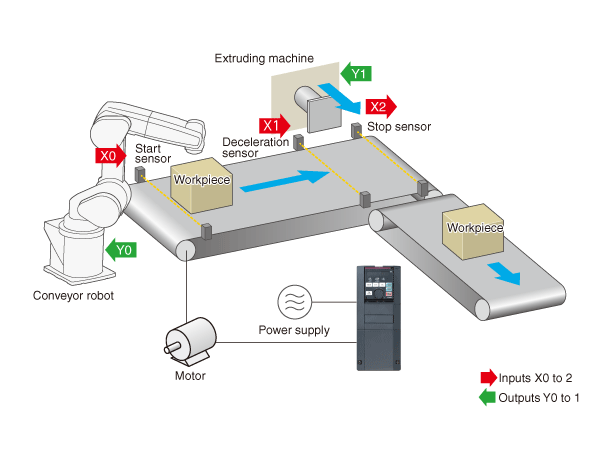

Conveying

ConveyingConveyor systems are essential for building production lines that connect each process, such as processing, filling, inspection, casing, and shipping. Different objects are transported in each process, requiring the system to have stable motor control even under variable load conditions. Mitsubishi Electric manufactures an expansive lineup of motors and drive devices that ensure stable transportation, realize energy savings, and reduce the equipment footprint on the shop floor.

Users Benefit

- Stable transportation performance

- Energy savings/smaller footprint

- Simple module configuration

Mitsubishi electric keeping you one step ahead of the competition

System example

Various innovative products helping you to realize the ideal system

Page Top

Solution

Understanding and providing the solutions that fit correctly for you

Realize stable transportation

Highly accurate control realizes stable operation with a speed fluctuation ratio of 1% even under variable load conditions.

Solution

Inverter advanced magnetic flux vector control

Capable of a high torque of 200% at 0.5 Hz (3.7K or less).

Even when quickly accelerating a heavy load from a low speed, smooth acceleration is possible. As the speed regulation is 1%, stable operation is ensured even when the load changes.

Click here for details

Page Top

Freely customize operation

Inverter operation can be freely customized, realizing inverter operation based on machine specifications.

Solution

Inverter PLC function

Inverter control such as operations triggered by input

signals, signal output based on operation status, and

monitor output can be freely customized based on machine specifications.

All machines can be controlled by a single inverter alone, and control can be dispersed as well.

Click here for details

Page Top

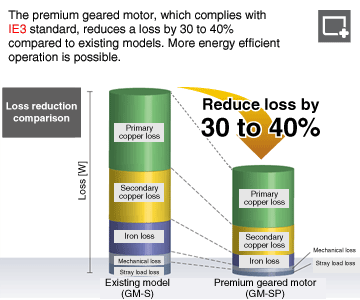

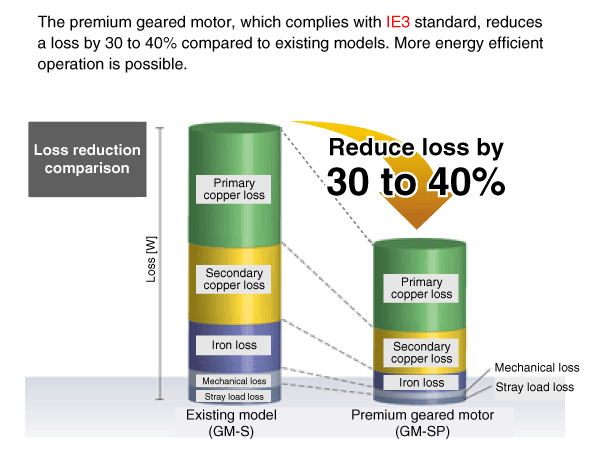

Energy-saving motors

Energy-saving operation using motors that comply with domestic and overseas strict energy efficiency laws and regulations drastically reduce running cost.

Solution

Geared motors

Geared motors conforming to top runner program standards are available. Used together with the inverter, reliable motor drive and constant torque are realized from the low-speed range. Energy-saving, high-performance factory equipment contribute to reducing total cost of ownership (TCO).

Click here for details

Page Top

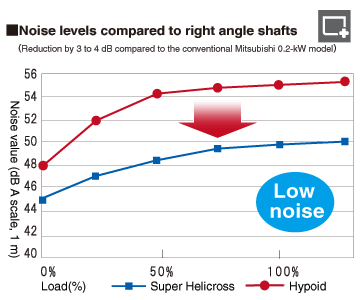

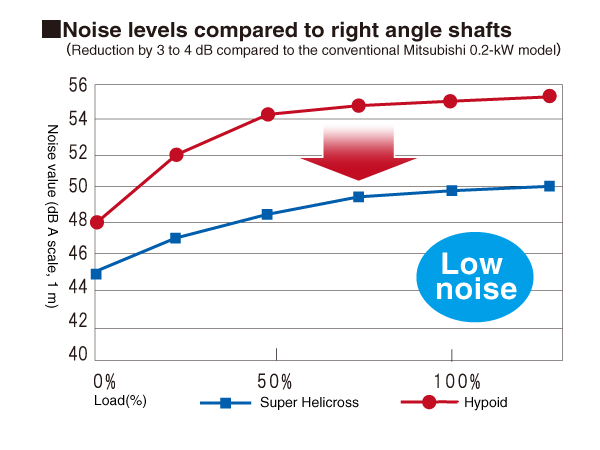

Low noise, low vibration, more compact

Smooth power transmission is realized using a geared motor equipped with a high-precision gear, contributing to low noise, low vibration and more compact product.

Solution

Geared motor right-angle axis

The Super Helicross Series is a lineup of high-precision, super-silent geared motors equipped with the first right-angle “Super Helicross Gears” that realize smooth power transmission. These products offer various features, such as low-noise, low-vibration operation, a long service life, and compact design. Specially designed oil seals are used to prevent grease leakage.

Click here for details

Page Top

Related products

Introducing various innovative products to solve your problems

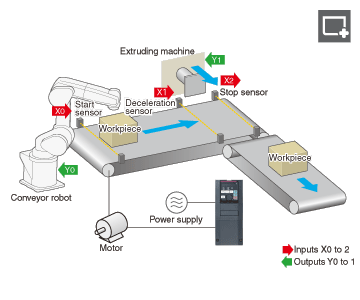

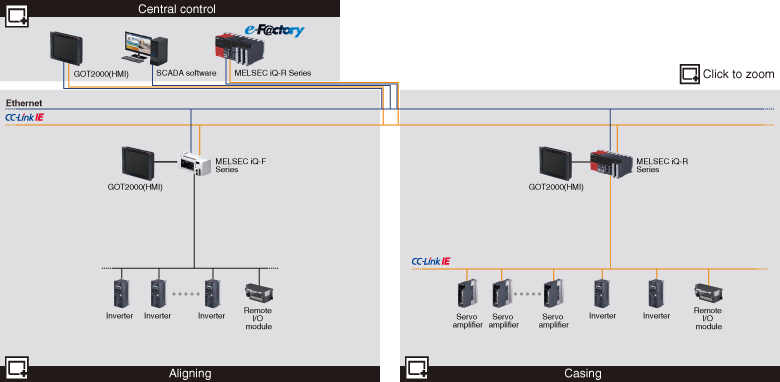

Casing

CasingProcess for casing products. Highly accurate synchronized control is required for aligning products to be picked up and then packed into cases. Mitsubishi Electric's factory automation products contribute to improving productivity and reducing production line downtime through equipment safety and preventive maintenance.

Users Benefit

- Safety system configuration

- Reduce maintenance staff load

Mitsubishi electric keeping you one step ahead of the competition

System example

Various innovative products helping you to realize the ideal system

Page Top

Solution

Understanding and providing the solutions that fit correctly for you

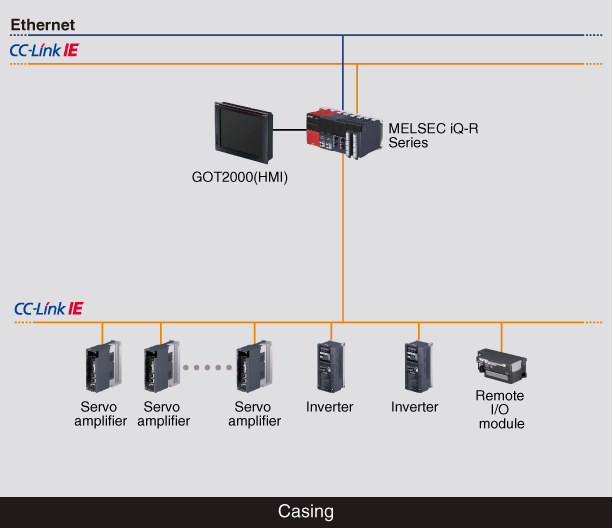

Improving productivity of complicated casing equipment

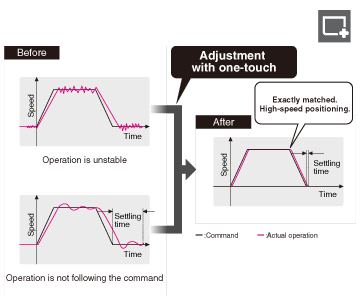

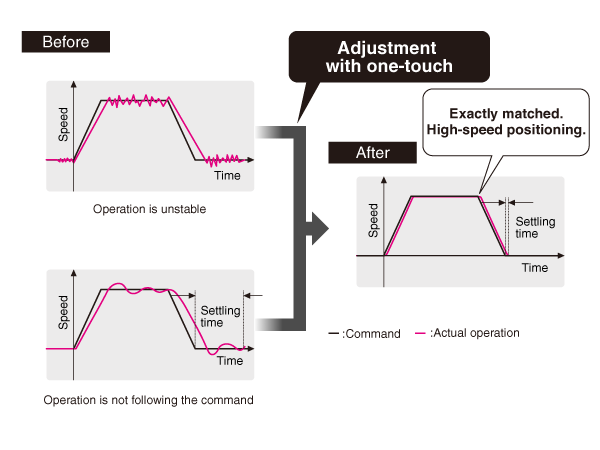

Optimum gain adjustment is completed in a short time. Machine performance is utilized to the fullest using the advanced vibration suppression control function.

Solution

AC servo

One-touch tuning

Mitsubishi Electric's unique "One-touch tuning" enables servo gain adjustment with one-touch ease.

Machine performance is utilized to the fullest using the advanced vibration suppression control function.

Click here for details

Page Top

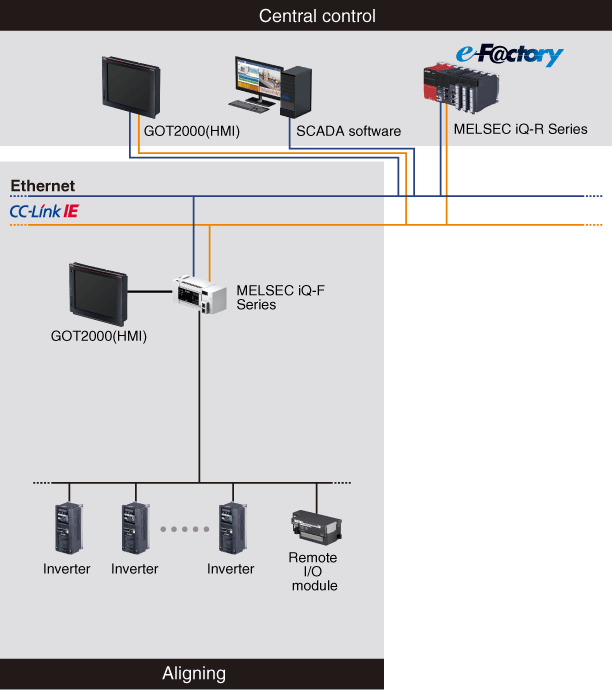

Smooth alignment operation easily configured

Equipped with highly compatible inverters, programmable controllers can easily control machine operation.

Solution

MELSEC iQ-F Series

inverter communication

command function

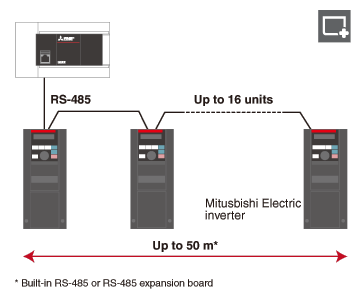

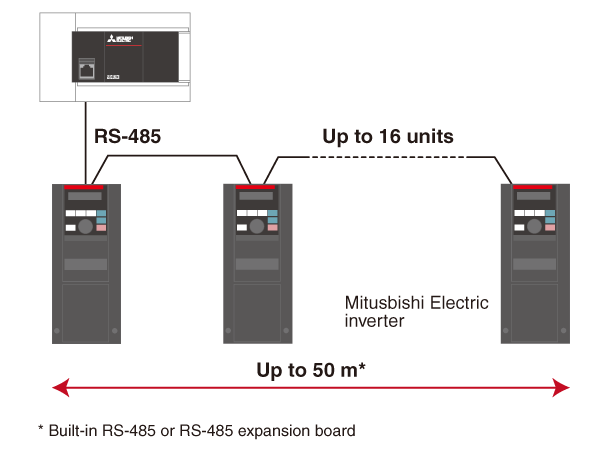

Equipped with a RS-485 communication port, MELSEC iQ-F Series programmable controllers support Mitsubishi Electric inverter protocol. Using a dedicated program, inverter operation and frequency setting can be done easily, reducing program development time.

Click here for details

Page Top

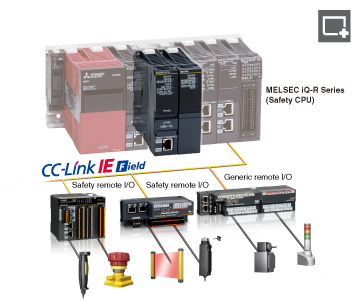

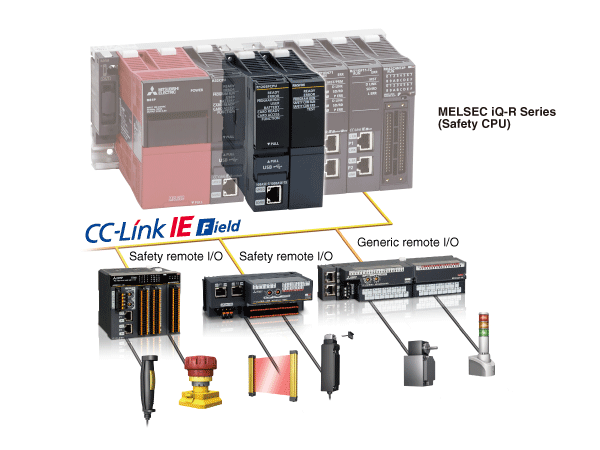

Safety system ensuring safety where operators and

machines work in collaboration

The safety CPU and safety devices ensure the safety of operators and facility protection, preventing operator injury during changeover and other activities.

Solution

Safety solution

To improve productivity in the production line, reducing downtime related to changeover and maintenance is necessary. Mitsubishi Electric offers a total safety solution that realizes "collaboration" between operators and machines using a large variety of products, such as safety programmable controllers and safety drive devices.

Click here for details

Page Top

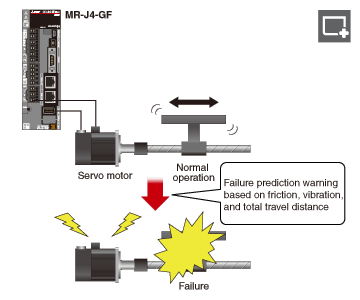

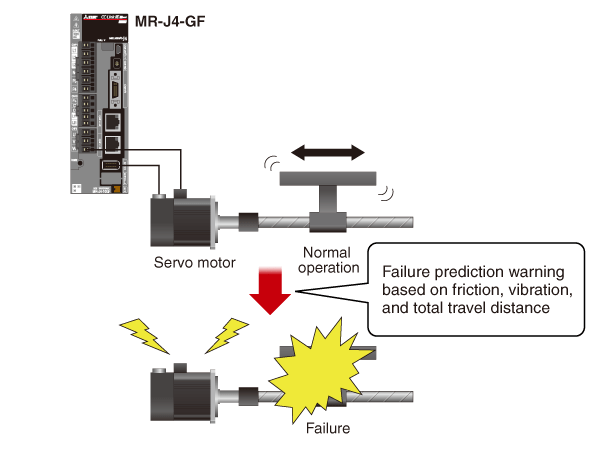

Maintenance at optimal time

By utilizing failure prediction data to schedule maintenance at optimal times, unplanned downtime is avoided, improving operation rates for the entire production line.

Solution

AC servo

Failure prediction warning

A servo amplifier predicts machine failure based on changes in a machine over time. Predictive maintenance is essential for minimizing the risk of machine failure and maximizing productivity.

Click here for details

Page Top

Related products

Introducing various innovative products to solve your problems

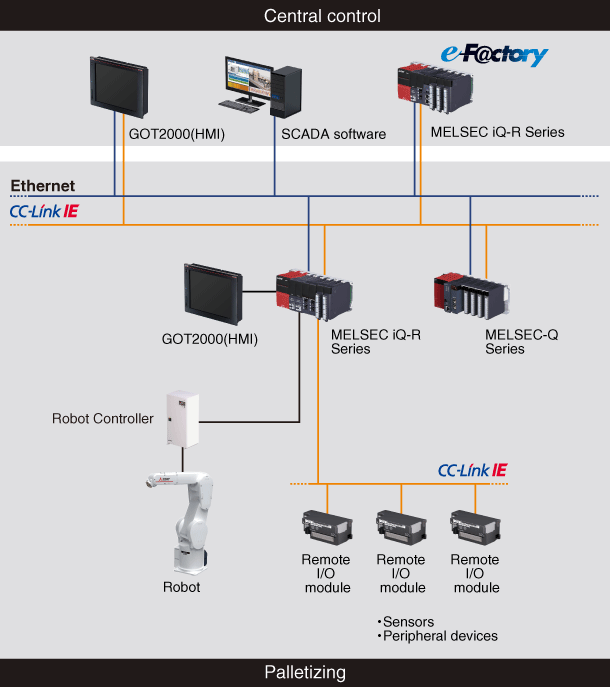

Palletizing

PalletizingProcess for stacking cases onto transportation pallets. Incoming cases are firmly grabbed, lifted up and stacked on the pallet in a specified pattern. Introducing an optimum automated system can solve many issues, realizing man-power savings and reducing the production cycle time.

Users Benefit

- Significant labor reduction

- Production cycle reduction

Mitsubishi electric keeping you one step ahead of the competition

System example

Various innovative products helping you to realize the ideal system

Solution

Understanding and providing the solutions that fit correctly for you

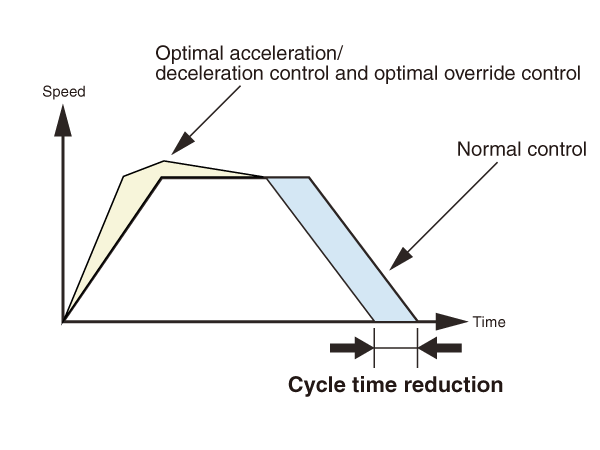

Introduction of robot reduces production cycle time

High-speed palletizing operation using a dedicated robot drastically reduces production cycle time.

Solution

Industrial robot

Optimal acceleration/

deceleration control

The introduction of industrial robots realizes a reduction in operators and heavy labor. High-speed motion control such as optimal acceleration/deceleration time control based on robot operating position and load conditions enables smooth, high-speed optimum palletizing.

Click here for details

Easily configure coordinated system with a robot

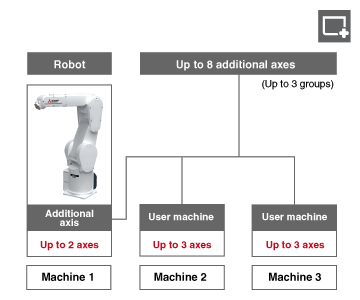

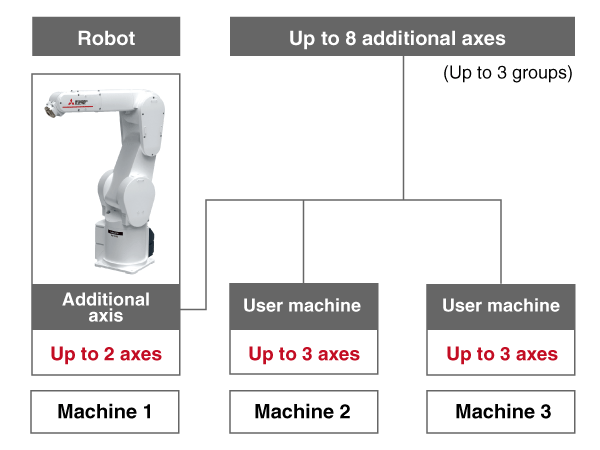

Peripheral machines such as traveling axis can be controlled via the robot controller. Additional axes can be operated as well, thereby improving productivity

Solution

Industrial robot

Additional axis function

Up to eight additional axes, such as robot traveling axis and separate turntable can be controlled via the robot controller. A coordinated system including a robot can be easily configured, as controlling the additional axes and user machines is done from the robot program and teaching pendant. This function expands the operating range, enabling the support of a wider range of applications such as one robot servicing multiple locations.

Click here for details

Sharing a large amount of data with peripheral devices

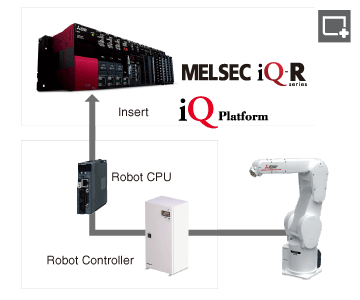

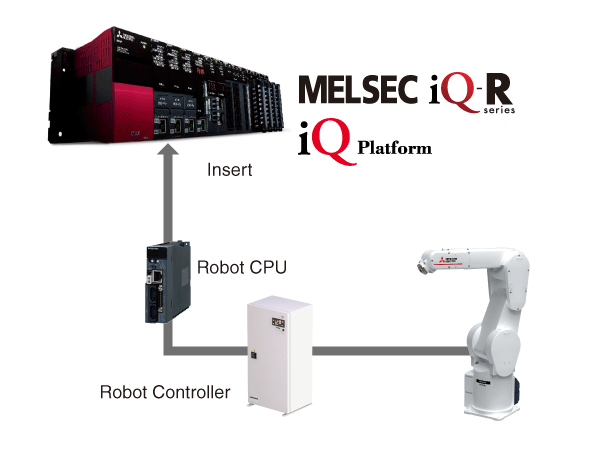

Coordination between factory automation products and an industrial robot realizes more advanced operation.

Solution

iQ Platform

Factory automation products such as the programmable controller and industrial robot can be coordinated to realize more advanced operation. The large amount of data managed by the programmable controller is transferred to the robot in real-time. Being able to share large volumes of data reduces wasted time.

Click here for details

Related products

Introducing various innovative products to solve your problems