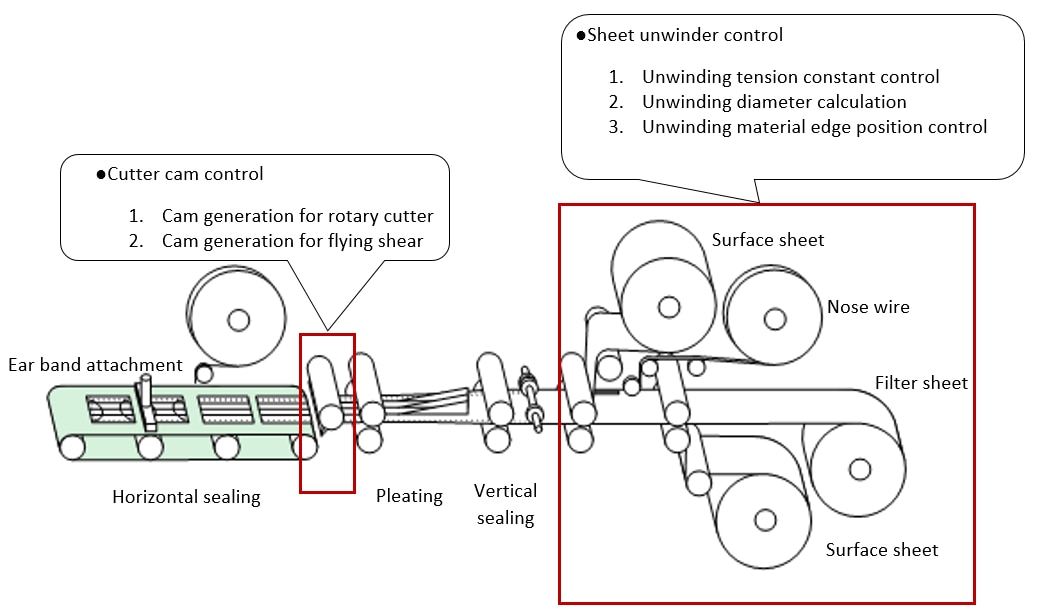

Challenges Faced by Mask Production Line

The first main challenge is to maintain the constant tension of the input material. As the line continues to run, the decreasing diameter of the sheet roll will result in changes in the sheet's tension. This may cause the material to be torn or there will be extra material.

In addition, another challenge faced is to cut the sealed sheets accurately at a high speed to achieve higher output.

iQ Monozukuri FACEMASK Solution

iQ-Monozukuri FACEMASK contains pre-developed function blocks to address the two issues. It is readily available & easy to use, only parameter settings are required. This will help to reduce the man-hour to design and build a new mask production line.

If you are looking into setting up facemask production line, lets fight this virus situation together! Contact us at ID@asia.meap.com for further discussion.

|