Solutions

Electricity/Electronic

Electricity/Electronic

(Compact LCD)

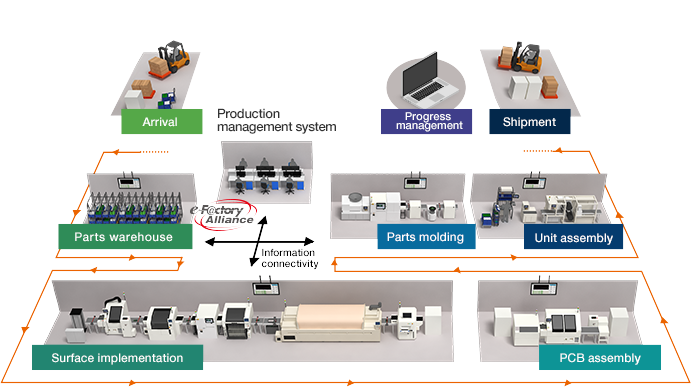

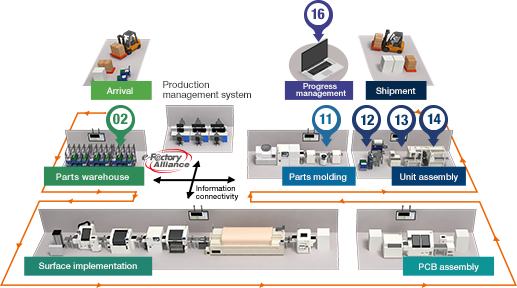

Electricity and electronic fields require elaborate and complex work, yet a high percentage of tasks are still performed manually. A major issue faced is how to automate the processes of part loading, surface implementation, PCB assembly, unit assembly and shipment in order to reduce human error. e-F@ctory helps provide a solution to this issue by providing robots equipped with force sensors and work support systems.

Arrival

-

01

Loading

Parts

warehouse

Surface

implementation

-

03

Solder

printing -

04

Chip

mounter -

05

Reflow

furnace -

06

Inspection

PCB assembly

-

07

Primary

assembly

PCB assembly

-

08

Flow-type

soldering -

09

Inspection

Parts molding

-

10

Injection

molding -

11

Deburring/

Polishing

Unit assembly

Shipment

-

15

Packing

Progress

management

02Parts warehouse

Error-proofing

Issues

Incorrect part selection/supply

Incorrect part selection/supply Process stops due to parts shortage

Process stops due to parts shortage

![]()

Solution

Prevent mistakes with a work instruction system

Prevent mistakes with a work instruction system Advance notification of shortages with a status indicator

Advance notification of shortages with a status indicator

11Deburring/Polishing

Deburring/Polishing

Issues

Complicated adjustments in order to machine workpieces of various shapes

Complicated adjustments in order to machine workpieces of various shapes Tool wear

Tool wear

![]()

Solution

Shorten start-up time with simple teaching

Shorten start-up time with simple teaching Detect wear amount with a force sensor

Detect wear amount with a force sensor

12Unit assembly

Bolt-tightening support

Issues

Incorrect assembly during high-mix, low-volume production

Incorrect assembly during high-mix, low-volume production Flexible support of production load fluctuations

Flexible support of production load fluctuations

![]()

Solution

Prevent mistakes with a work instruction system

Prevent mistakes with a work instruction system Optimize to suit production status

Optimize to suit production status

13Inspection

Force sensor application

Issues

Manual work by humans is required to connect connectors to inspection units

Manual work by humans is required to connect connectors to inspection units

![]()

Solution

Full automation of inspection process through introduction of a robot equipped with a force sensor

Full automation of inspection process through introduction of a robot equipped with a force sensor

14Packaging

Packaging

Issues

Seal suited to workpiece, cutting operation and cut length correction necessary

Seal suited to workpiece, cutting operation and cut length correction necessary

![]()

Solution

Simplification of equipment start-up with a seal/cut mechanism and correction function

Simplification of equipment start-up with a seal/cut mechanism and correction function

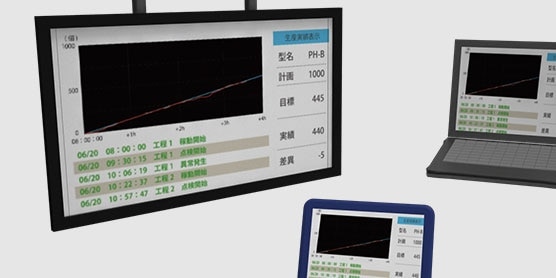

16Progress management

ANDON

Issues

Visualization of production status is time-consuming and cumbersome

Visualization of production status is time-consuming and cumbersome Can’t install status indicators for the sake of visualization alone

Can’t install status indicators for the sake of visualization alone

![]()

Solution

Able to efficiently build and operate systems not only capable of status visualization on large screens, but also tablets and computers. Features a signage function to improve the added-value of the visualization system

Able to efficiently build and operate systems not only capable of status visualization on large screens, but also tablets and computers. Features a signage function to improve the added-value of the visualization system