Solutions

Automotive/Automotive Parts

Automotive/

Automotive Parts

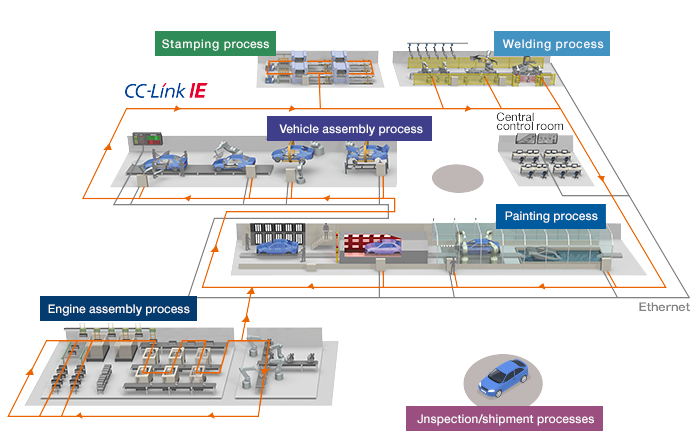

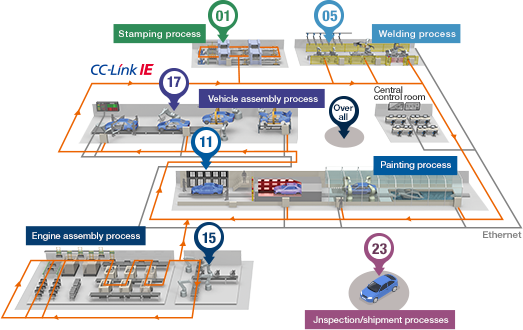

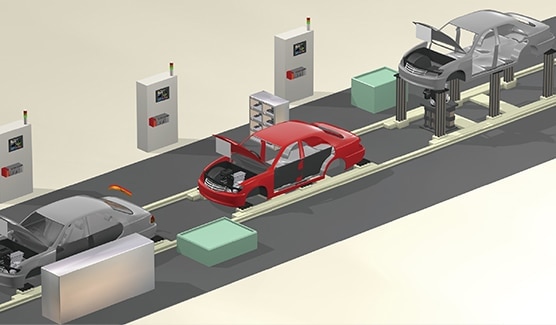

In vehicle manufacturing plants that handle a vast number of parts and wide variety of processes, there is a need to solve various issues such as responding to mixed production of many different car models, improving production speed and quality, considering worker safety and engaging in environment-oriented initiatives.

e-F@ctory helps provide solutions to the issues customers face by offering optimal solutions through forming common platforms and alliances with many different partners.

Stamping

process

-

01

Coil set

-

02

Blanking

-

03

Molding (press)

Welding

process

-

04

Inner frame welding

-

05

Outer join welding

-

06

Door welding

-

07

Unloading inspection

(performed by

human operator)

Painting

process

-

08

Electro-deposition coating

-

09

Sealer application

-

10

Finish coating

-

11

Paint inspection

Engine

assembly

process

-

12

Casting

-

13

Machining

-

14

Heat

treatment

Vehicle

assembly

process

-

16

Instrument panel

installation -

17

Glass

attachment -

18

Bumper installation

-

19

Engine installation

-

20

Car seat installation

-

21

Tire

mounting

-

22

Door

installation

Inspection/

shipment

processes

-

23

External inspection

-

24

Internal inspection

-

25

Other

inspections -

26

Shipment

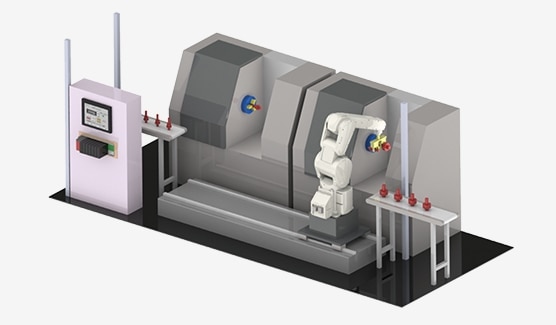

01Coil set

Issues

Want to perform loading/unloading to/from processing machines automatically

Want to perform loading/unloading to/from processing machines automatically Concerned about cost of installing a robot

Concerned about cost of installing a robot Want to further improve the productivity of processing machines

Want to further improve the productivity of processing machines

![]()

Solution

Installing a robot increases production volume approximately 1.5 times, compensating for equipment depreciation in about one year

Installing a robot increases production volume approximately 1.5 times, compensating for equipment depreciation in about one year Flexibly supports different product types and production adjustments, and reduces dangerous work (Note: Calculated using Mitsubishi Electric conditions and calculations)

Flexibly supports different product types and production adjustments, and reduces dangerous work (Note: Calculated using Mitsubishi Electric conditions and calculations)

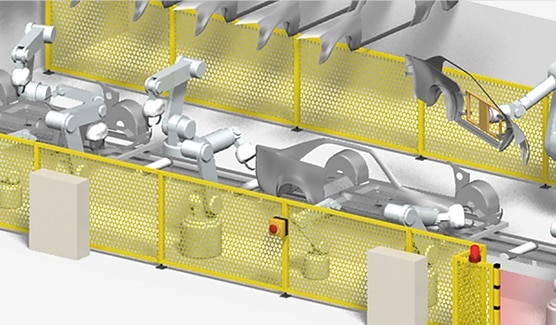

05Outer join welding

Issues

Want to ascertain the status of each device in the welding process

Want to ascertain the status of each device in the welding process

![]()

Solution

By installing a PLC, the values of designated devices can be monitored in real-time with arbitrary sensitivity and timing, which leads to preventive maintenance

By installing a PLC, the values of designated devices can be monitored in real-time with arbitrary sensitivity and timing, which leads to preventive maintenance

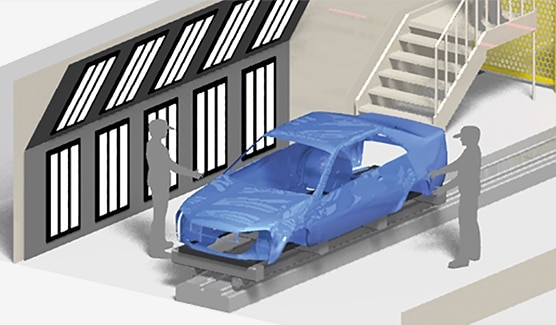

11Paint inspection

Issues

In the past, operators inspected accuracy visually and manually. With consideration to mass production, want to shorten time required to inspect each workpiece and eliminate measured value variation due to operators’ level of experience

In the past, operators inspected accuracy visually and manually. With consideration to mass production, want to shorten time required to inspect each workpiece and eliminate measured value variation due to operators’ level of experience

![]()

Solution

The tasks of lot no. scanning, accuracy inspection and measured value recording are all performed automatically, therefore shortening inspection time. Able to perform batch inspection with a sensor jig, therefore creating an inspection system not dependent on operator experience. Reduces manufacturing costs by reducing number of people required for inspection work

The tasks of lot no. scanning, accuracy inspection and measured value recording are all performed automatically, therefore shortening inspection time. Able to perform batch inspection with a sensor jig, therefore creating an inspection system not dependent on operator experience. Reduces manufacturing costs by reducing number of people required for inspection work

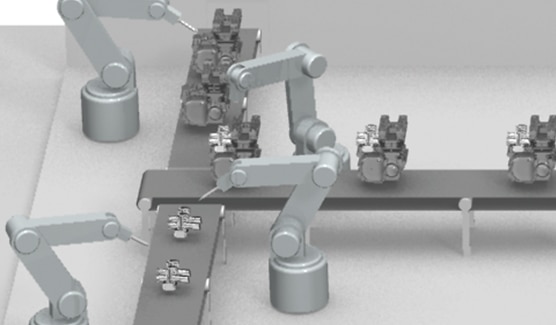

15Assembly

Issues

Human error occurs, such as missing a machining step, therefore machining in the wrong order. Want to manufacture products that have passed through the necessary processes with certainty and create a system that can manage process sequence

Human error occurs, such as missing a machining step, therefore machining in the wrong order. Want to manufacture products that have passed through the necessary processes with certainty and create a system that can manage process sequence

![]()

Solution

Through individual management of parts for machining, able to ascertain whether or not parts have been machined in line with the correct process sequence. Workpiece individual management is possible with a laser engraving + barcode reader, and major additional machining is not required

Through individual management of parts for machining, able to ascertain whether or not parts have been machined in line with the correct process sequence. Workpiece individual management is possible with a laser engraving + barcode reader, and major additional machining is not required

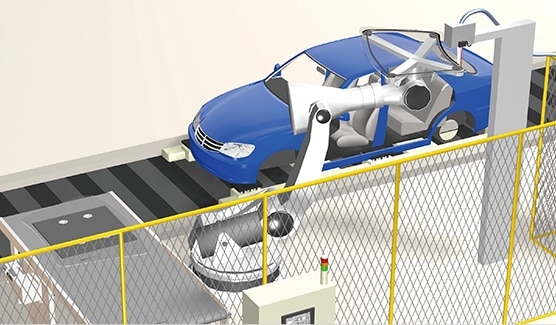

17Glass attachment

Issues

Want the coating apparatus to be able to trace the glass surface so that adhesive agent is applied evenly

Want the coating apparatus to be able to trace the glass surface so that adhesive agent is applied evenly

![]()

Solution

Correction of nozzle position with a laser displacement sensor

Correction of nozzle position with a laser displacement sensor

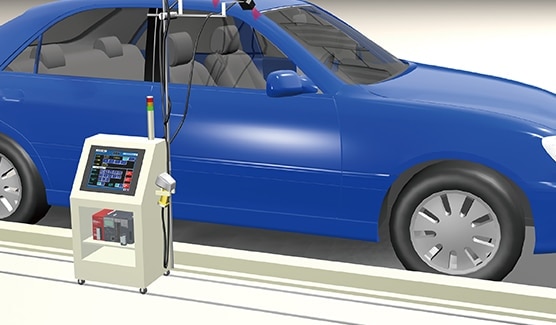

23External inspection

Issues

Would like to automate inspection work performed manually and visually by operators

Would like to automate inspection work performed manually and visually by operators Would like inspection results to have traceability

Would like inspection results to have traceability Many man-hours are required to develop programs for sensors

Many man-hours are required to develop programs for sensors

![]()

Solution

Automation is possible by installing sensors for gap measurement

Automation is possible by installing sensors for gap measurement Inspection history can be traced using logging data

Inspection history can be traced using logging data Less man-hours required for development due to a "single-tool" engineering environment and sample programs

Less man-hours required for development due to a "single-tool" engineering environment and sample programs

Overall

Issues

Want to reduce the time it takes for shop floor equipment to recover after a fault has occurred

Want to reduce the time it takes for shop floor equipment to recover after a fault has occurred Want to easily carry out regular backup of system data for the overall line

Want to easily carry out regular backup of system data for the overall line Want to prevent trouble by assessing signs of power abnormalities in equipment

Want to prevent trouble by assessing signs of power abnormalities in equipment

![]()

Solution

GOT backup/System recovery without a computer using a restore function

GOT backup/System recovery without a computer using a restore function Batch backup of all system data with the integration engineering tool

Batch backup of all system data with the integration engineering tool Prevent sudden breakdowns by constantly monitoring electric current (or electric power)

Prevent sudden breakdowns by constantly monitoring electric current (or electric power)